PRINT QUALITY CONTROL

IMAGES

Color images print quality control can be carried out either by learning a reference (golden) document in the machine, or by comparison with the original PDF print file (after geometric and colorimetric calibration). Axode solutions allow the detection of printing defects, color shift, at very high resolution and on large formats, while tolerating deformations coming from paper, transport, reasonable tolerances for color registration, etc.

PRINT QUALITY

Print quality control is essential in digital printers because of their potential hazards: missing jets, permanent jets, color misalignment, heads misalignment, contrast, etc. There are many verification methods, such as checking specific printed patterns. But unlike offset, 2 "good" pages can frame a defective page. If the printed content is sensitive and variable, then all printed pages should be 100% verified against the original PDF file.

COLOR REGISTRATION

All printing presses (offset, digital, etc.) must control the registration of the primary colors they use. Axode software can detect registration errors that the discerning eye can detect (typically 200 µm) but also measure deviations with the precision of a drop (typically 20 µm) and transmit in real time a correction instruction to the inkjet controller (close loop).

SPECIAL & INVISIBLE INKS

The use of special inks is systematic on security documents as protection against counterfeiting (invisible fluorescent ink, infrared reactive, heat reactive, etc.). Given that they must be applied by printing stations or dedicated inkjet heads, they require specific control cameras, both to check their characteristics and guarantee their purpose (presence, position, intensity, compliance, etc).

OVI

Optical variable inks are used in security documents to print objects, shapes, logos, and to protect these documents against counterfeiting. The printing of these shapes constituting a specific step in the printing process, it is necessary to check their conformity (presence, position, color) and especially the print quality (lack or excess of ink on the outline of the object).

CLI/MLI

The transparent outer layers of identity cards and datapages allow the integration of security marks in the thickness of the material, whether in depth (engravings, micro-text, etc.) or in superthickness (CLI/MLI, touch effect elements, etc.). The CLI/MLI is a high-resolution lens allowing the laser customization of 2 interlaced images, and requires specific high-resolution control to guarantee the optical qualities (regularity, compliance, no crushing, burns, etc.).

TRANSPARENT SECURITY WINDOW

Due to their multilayer structure, identity cards can form a specific security element: by making cuts in the inner printed layers, the outer laminated layers provide a transparent window. By working with lamination layers, this window can be transformed into a lens. It is therefore necessary to check the characteristics of this window (presence, position, quality, transparency) but also to validate the correct alignment of the internal printed layers.

HOLOGRAMS

Being particularly difficult to counterfeit, holograms are a very widely used security element on security documents. Their complex optical behavior, the technology of their network, the type of support (transparent or metalized) implies a camera control with particular and multiple means. Whether it is in rolls at the manufacturer, during the application at the printer, it is necessary to check the presence, position, contrast, image quality, quality of the application, centering of the image, etc.

MAGNETIC TAPE

The application of magnetic tape on a plastic card can generate errors inherent in the process of applying a magnetic film on its carrier: position, linearity, tears, application of excess particles, absence of the magnetic layer, surface condition of the substrate, presence of a foreign object, etc. The control can be carried out on cards, or on complete web before cutting.

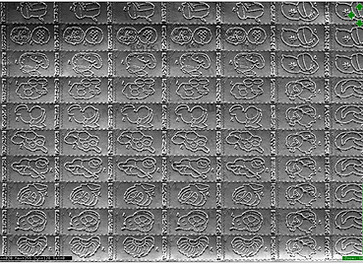

EMBOSSING, ENGRAVINGS, EMBOSSING AND BRAILLE

Some paper or plastic documents allow surface work to include security elements: embossed bank cards, deeply engraved texts or images, touch-sensitive embossing, Braille coding of medication boxes, etc. Axode’s principle of acquiring surface finish images allows the control of this information by variation of thickness, which makes it possible to validate its quality, position and legibility.

SELECTIVE VARNISH

The application of a varnish layer on a printed document improves its aesthetic appearance by a slight glossy effect, especially if it is a selective varnish, that is to say covering only certain parts or objects in the document (images or text). With a surface finish analysis camera, Axode can control the presence of varnishing, the quality (too low or too generous application) and the integrity of the varnish image. But above all the correct alignment of the varnished image with the printed image.

CUTTING

The cutting of documents is finishing operation which is found in multiple processes: cutting of plastic cards in a production in sheets, cutting of windows or logos in a security document, stripping of labels produced in rolls, etc. This operation requires an on-line control such as presence and quality of the cuts, centering of the printing, etc. The cutting is often accompanied by a folding and gluing on-line which also requires a control: glue points, control of the dimensions, quality of edges (lack of fibers), etc.

LAMINATION

The production of plastic cards requires the verification of the surface finish of the outer layers. Axode lamination control cameras use a special technique to accurately visualize and verify the surface of the card. This control detects the presence of defects that would not be visible to the naked eye: impacts, scratches, thickness variations around the RFID chip, but also allows to check the compliance of any marking, embossing, micro-text, etc.

APPLICATION

The automatic application of objects on a document is used in many markets: holograms, safety labels, scratch-off labels, perfume samples, discount coupons, etc. In all cases a position control is essential. For some products, such as prepaid cards or gift cards, the card and its carrier document are serialized and matching must be verified in real time against a database.

CONTACT SMART CHIP

The "smart chip" is integrated into a machined cutting in the thickness of a plastic card. If the content control requires dedicated machines allowing the application of contact smart chips in the machine cycle, the camera control can, even at high speed, check the position, shape, depth of the cutting provided for this purpose, then the presence, position and orientation of the chip after application.

PERFORATION

The perforation of a document is either functional (micro-perforation for the precut of a cheque, a coupon, perforation of stamps' sheets) or a security mark (customization of passports, identity documents). In any case it requires verification of its alignment with the print, and the quality of each through hole.

HOLOGRAPHIC TAPE

As an alternative to unitary holograms, the application of a continuous metalized holographic tape makes it possible to include a holographic object on small, continuously produced documents. For example, tax labels for cigarette packages. The camera control consists in verifying that the operator uses the right tape, but above all in detecting errors resulting from the application itself: position, linearity, tears.